Automation and Digitalization

The key to success in developing microbial production processes for bio-based compounds is to find a near-optimal combination of producer strain and bioprocess conditions. The solution of such a bi-level optimization problem (i.e. strain and bioprocess) is usually very time-consuming and depending on the available technical equipment also very material and thus cost intensive. To overcome this limitation we build on the classical Design-Build-Test-Learn cycle and develop lab automation solutions to accelerate it.

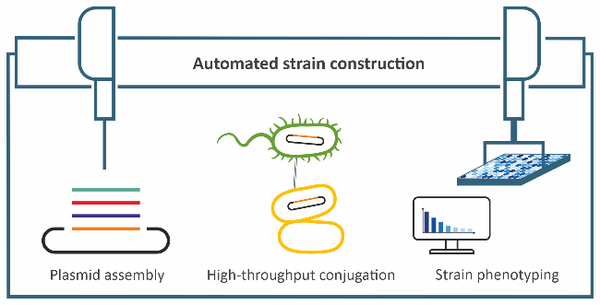

Currently, the construction and optimization of microbial production strains by rational molecular engineering are mainly performed manually. Modularization, standardization and automation of strain engineering are urgently needed to significantly accelerate these steps and thus generate innovations more quickly.

The AutoBioTech innovation lab within the BioökonomieREVIER project aims to change this: here, automation technologies for the rational metabolic engineering of microbial strains are being developed. The initial focus is on industri ally established microorganisms such as Escherichia coli, Corynebacterium glutamicum or Pseudomononas putida, whose genetic blueprints are well known and for which reliable molecular cloning methods have been established.

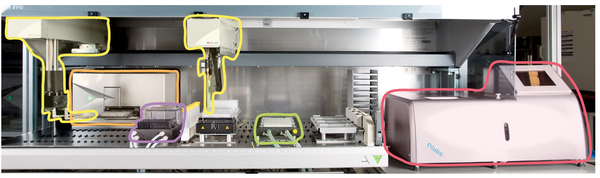

By accelerating strain construction, a much broader use of the natural biodiversity of microorganisms is made possible. In order to generate knowledge and marketable bioprocesses from this, the new strain libraries must be characterized quickly and thoroughly. We have established the Mini Pilot Plant technology to automate individual experimental steps such as media preparation and optimization, inoculation and time- or signal-triggered sampling of (fed)-batch cultivation experiments on a microplate scale.

In the DigInBio project sophisticated digital workflows are being developed to enable completely autonomous phenotyping experiments. In order to not only to speed up processes but also reduce the number of required experiments by learning new things we develop and apply tailored software tools. These are based on universal programming languages, such as Python, and enable the modelling, characterization and optimization of microbial bioprocesses.

The Helmholtz Innovation Lab MiBioLab tries to bridge the gap between academic and industrial research activities in the field of lab automation for bioprocess development. It strives for translation of current and next generation technologies into industrial research, which also includes contract research and know-how transfer projects with SMEs and industrial partners.

Research

groups

Current

projects

AutoBioTech Automatisierungstechnologien zur Entwicklung industrieller Prozesse für hochwertige Produkte

DigInBio Digitalisierung in der industriellen Biotechnologie

MiBioLab Microbial Bioprocess Lab