Gas Separation Membranes

The department develops ceramic membranes for gas separation- an area which has considerably expanded for the past few years due to the fact that membrane separation technology offers high energy efficiency through process intensification and cost reduction.

Pure oxygen and hydrogen gas supply is very important for a number of processes. Potential applications can be found in H2 based systems for mobile and stationary applications, power plant of different concept (post- and pre-combustion, oxy fuel), cement, chemical and petrochemical industries etc. Another focus is on membrane reactors, in which these gases, together with other substances (including CO2 utilization), are converted into the desired product.

The department consists therefore of three teams, specialized namely on the development of oxygen-permeable membranes, hydrogen-permeable membranes and nanostructured membranes.

Objectives of the three teams are i) the development of materials including optimization of conventional material candidates but also establishing of novel promising systems; ii) manufacturing of thin asymmetric membranes for the efficient gas separation; iii) proof of concept by means of modules and membrane reactors consisting of scalable thin-film membranes with industrially relevant geometry and size for demonstration of technology readiness level.

The definition of a material candidate suitable for certain membrane application addresses a number of issues as its performance, thermo-chemical/mechanical and phase stability, compatibility with other components, etc. and needs to realize an appreciable compromise between various material properties under relevant operating conditions.

Depending on the separation task and the properties of the selected material, dense ceramic membranes with oxygen ionic/protonic conductivity or mixed oxygen ionic/protonic-electronic conductivity are developed, as well as microporous crystalline or amorphous inorganic membranes.

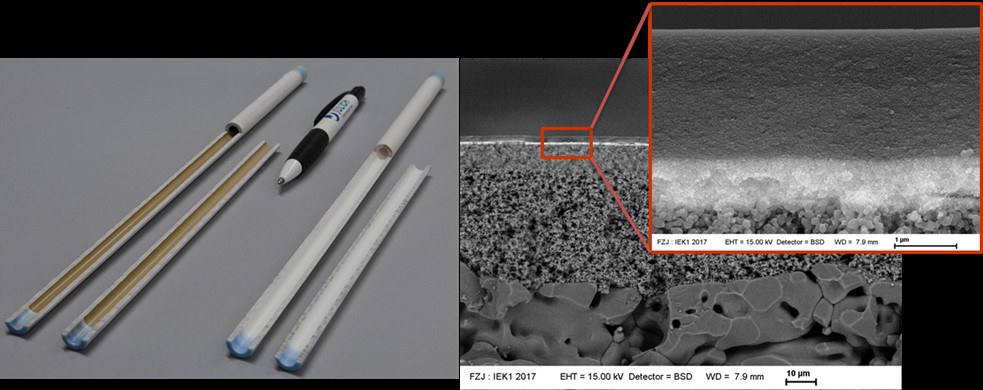

By means of advanced, reproducible and scalable fabrication techniques available at IEK-1, e.g. tape casting, screen printing, spin and dip coating in a clean room, PS-PVD etc., membranes of different thicknesses (in the nanometer to micrometer range), microstructure and final geometries are fabricated on either ceramic or metallic substrates.

Along with these activities, micro-structuring (for gas flow optimization) and component manufacture (scalable membrane components for use in proof-of-concept modules) present significant part of our R&D activities.

Apart from the development efforts to form defect free and highly performing membranes for the targeted energy and environmental applications, the team carries out detailed fundamental research to elucidate the interrelation of properties as composition, microstructure, performance and stability.