Solid Oxide Fuel Cells

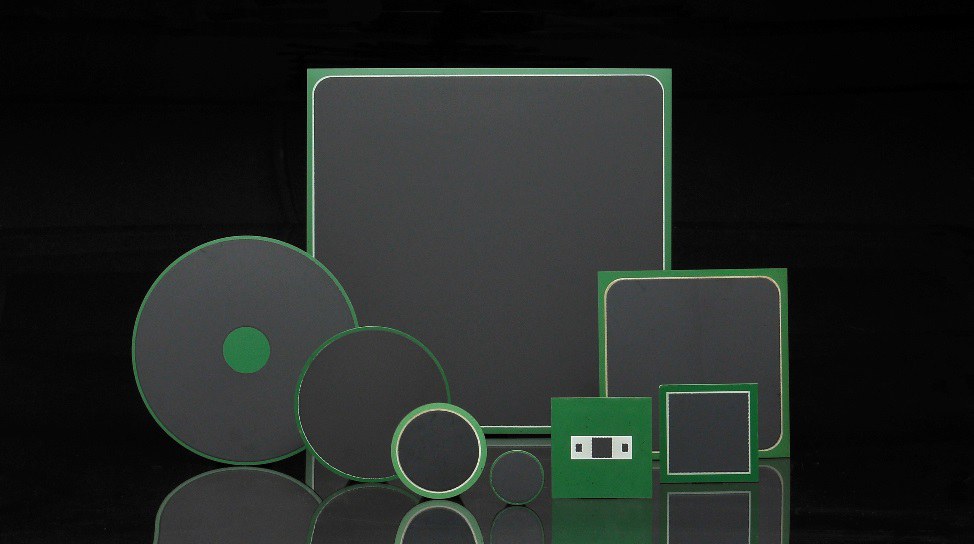

The department of Solid Oxide Fuel and Electrolysis Cells (SOFC and SOEC) concentrates on material development and manufacturing methods for solid oxide fuel and electrolysis cells, mainly based on ceramic powder processing. The main focus is the development of new materials and the optimization of the microstructure of functional components.

Being part of the future energy system

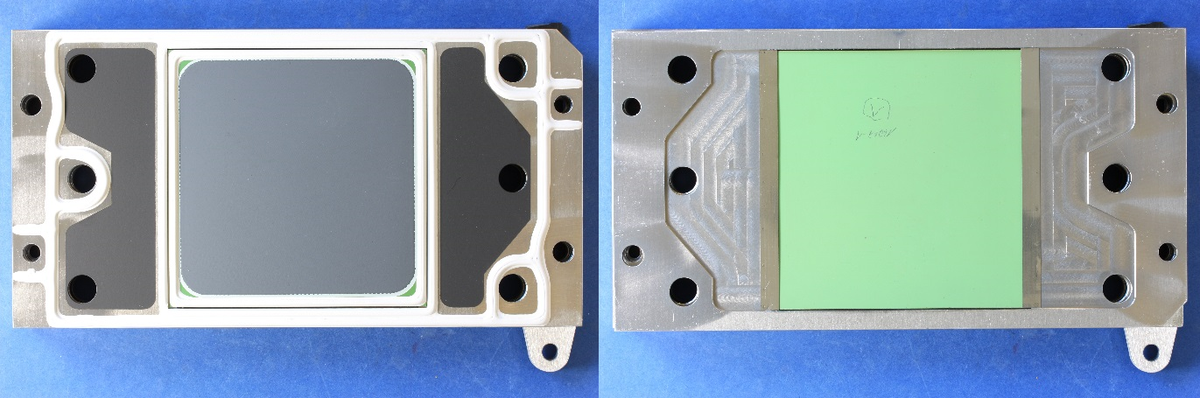

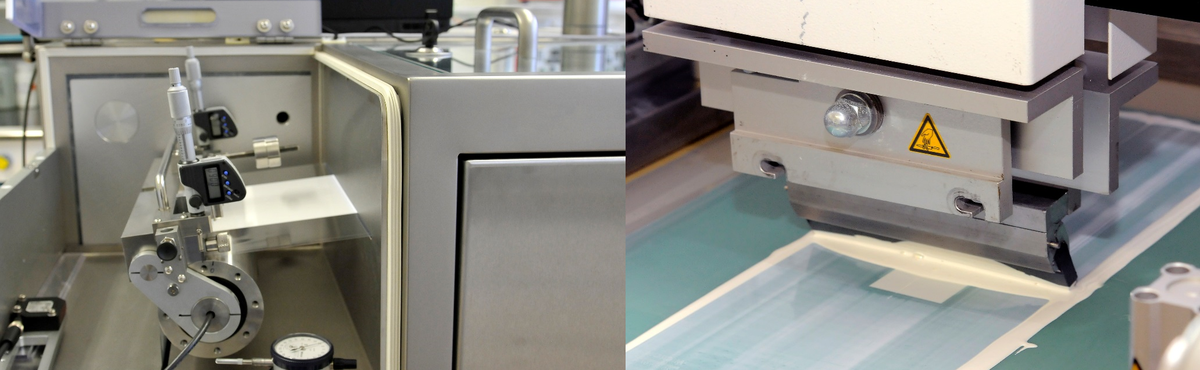

At IEK-1, SOC research focuses on cells, contact layers and interconnect protective layers. Research and development starts with the synthesis of suitable materials or the purchase of commercially available powders and their conditioning: ranging from raw materials and intermediate products (slips, pastes, suspensions), layers, components, and parts to scaling up in terms of component size, homogeneity, and reproducibility as appropriate for application in a pilot plant. For the manufacturing processes, mostly powder-based methods from metal and ceramic powder processing are applied, such as pressing, tape casting, screen printing, or wet spraying. If certain properties are required for functional layers, thin-film processes (PVD, sputtering), precursor-based techniques such as sol-gel processes (spin or dip coating, inkjet printing) and thermal spray technologies may also be applied. Studies on the degradation of SOCs and intensive post-test analyses of fuel cell stacks round out the research portfolio.

Enabling easy access to energy for everyone

In addition to our long-standing expertise in oxygen-ion based SOFC research, we work on high-temperature electrolysers to produce hydrogen in steam electrolysis or syngas in co-electrolysis and on proton-conducting fuel and electrolyzer cells (PCFC, PCEC). The focus are on the development of adapted electrodes for cells, their characterization and post-test analysis of operated cells from stacks.