Team Particle-Based Processing and Sintering

The team “Particle-based processing and sintering” provides net-shaping and sintering technologies, which can be applied for metallic and ceramic powders. A specific focus lies on sintering technologies, which enable superpositioning of pressure and/or electric field, aiming at full densification of the material.

Net-Shaping of Ceramic and Metallic Powders

The team deals with the net-shaping of metallic or ceramic powders by powder compaction, dip coating, tape casting or powder injection molding. A specific expertise exists in the processing of parts with well-defined porosities up to 80 Vol. %, which can be used e.g. as heat exchangers, porous transport layers, electrodes or metallic supports of electrochemical devices like fuel cells or gas separation membranes. Furthermore, we are able to manufacture metal-ceramic composites with layered structures and tailored interfaces.

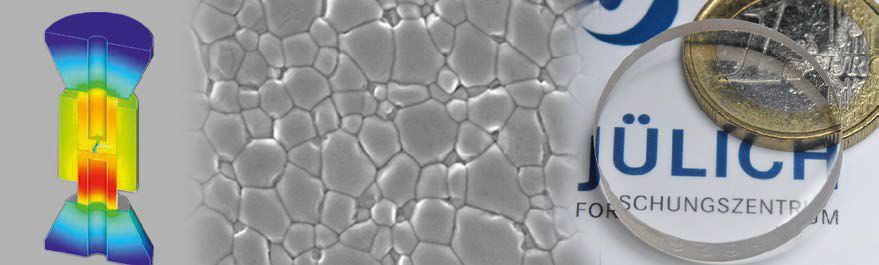

Sintering under Pressure And/Or Electrical Field

Different sintering techniques are available to densify a wide range of ceramic and metallic powders (yttria, ceria, tungsten, titanium, etc.) up to the theoretical density. Three field-assisted sintering/spark plasma sintering (FAST/SPS) devices enable rapid densification of ceramic, metal or composite powders. Here, temperatures up to 2,200°C and pressures up to 100 MPa can be achieved with graphite tools. Higher pressures up to 400 MPa are possible with alternative tool materials. Other modes of operation are flash sintering with AC and DC voltages up to 1000 V accompanied by external heating via induction coil or MoSi2 heating element as well as ultra-fast high temperature sintering (UHS) by resistance heating of carbon felts. A hot press (HP) with a MoSi2 heating element enables sintering at temperatures up to 1600°C under vacuum, air and argon up to maximum load of 100 kN. A custom made sinter forging device equipped with programmable power source, electromechanical testing system and optical laser scanners enables in-situ measurement of sintering parameters like viscosity, sintering stress and viscous Poisson´s ratio under electric field.